Machines

A digital manufacturing workshop

accessible to all!

Machines

To make a reservation, just click on the machine concerned! If you need help, click here to watch the tutorial of the booking module (in French).

Crédit Photo : erm-fabtest

Crédit Photo : erm-fabtest

This digitally-controlled milling machine is used to produce parts or elements by removing material using milling cutters.

The Pocket NC V2-10 enables work on 5 axis and on a wide variety of materials ranging from machinable wax to G5 titanium, wood, 6061 aluminium and 303 stainless steel.

Features

- Machining strokes 115mm in X, 128mm in Y, 90mm in Z, -25/+135° in A, continuous rotation in B

- Spindle 200W 2,000 to 10,000 rpm

- Clamps ER11 and ER40

Crédit Photo : erm-fabtest

5-axis digital mini-milling machine – Pocket NC V2-10

Perform your most demanding 5-axis machining operations on a wide variety of materials

Crédit Photo : Elektormagazine

Crédit Photo : Elektormagazine

The Wazer is the first “desktop” waterjet cutting machine. The principle of waterjet cutting is simple: water is projected at extremely high pressure (between 4,000 and 6,000 bars), to which an abrasive agent (garnet sand) is added. The latter, carried by the power of the high-pressure jet, can reach a speed of Mach 2.5 (2.5 x the speed of sound) and thus enable the cutting of very hard elements.

Materials that can be cut with this machine:

Marble ( 12.7 mm Max) / Glass ( 15.8 mm Max) / Aluminium ( 12.7 mm Max) / Steel ( 4 mm Max)/ Silicone ( 12.7 mm Max) / High-density polyethylene (HDPE) ( 12.7 mm Max) / Carbone ( 6.3 mm Max) / Carbon fibres ( 4.78 mm Max).

This list is not exhaustive; please, contact us to check if your material is compatible.

Cutting surface:

305×460 mm

Crédit Photo : Elektormagazine

Wazer Water jet cutting

Cut the toughest materials in no time!

Crédit Photo : TROTEC

Crédit Photo : TROTEC

In order to use the Trotec Speedy 300, you will need to come with your vectorised cutting file in .svg or .pdf format (CAD or graphics editing software such as Illustrator, Photoshop, etc.) and prepare only one file per sheet.

For student architects, pleaser refer to our laser cutting instruction leaflet (in French).

You can also take part in one of our training courses or come and practice your drawing at the Fablab.

It will then be necessary to run this file through the proprietary TROTEC JobControl software to start the cutting/engraving process.

All you have to do is let your imagination run wild and the machine will do the rest!

Features

- Power: 100 W

- Part volume: 729 mm x 433 mm x 200 mm

- Materials for cutting of engraving: plexiglas, wood, textile, paper, glass, cardboard, etc.

- Thickness according to materials: MDF/CP/PMMA = 10 mm, Rough wood = depending on the type, Glass/stone: engraving only

Only the first 15 / 30 minutes will be charged at the time of booking. The balance is to be paid on site.

Crédit Photo : TROTEC

Laser cutting

Cutting or engraving materials to quickly produce prototypes of your projects.

Crédit Photo : Sawgrass

Crédit Photo : Sawgrass

Thermal sublimation is a rapidly growing in popularity and capability.

The images are printed in a mirror image, using a special printer, on a heat-resistant transfer paper. Once printed, the images are transferred to the final substrate using a heat press.

You can book our sublimation printer alone and come with your sublimable objects, or you can book directly and include an object to sublimate, provided by us: mugs, mouse pads, t-shirts, caps and masks.

You can also join one of our training sessions.

Please specify the type and number of objects you wish to sublimate in the “total duration desired” section.

Price of a consumable + printing:

| Reduced rate | Normal rate | Business rate | |

| Mug | €7 | €10 | €15 |

| Mouse pad | €8 | €11 | €16 |

| t-shirt | €12 | €17 | €25 |

| Cap | €8 | €11 | €16 |

| Mask | €7 | €10 | €15 |

Only the first 15 / 30 minutes will be charged at the time of booking. The balance is can be paid on site at Fablab’s.

Crédit Photo : Sawgrass

Sublimation printer

Personalise your objects (clothes, mugs, masks, mouse pads, etc.) with sublimation transfer!

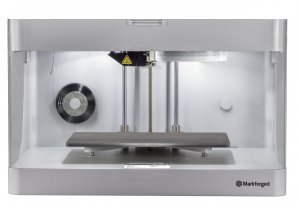

Crédit Photo : Markforged

Crédit Photo : Markforged

The 3D printer from Markforged is the first of its kind, using the new CFR technology: Continuous Fiber Reinforcement. This method, based on FDM printing, makes it possible to add, inside the printed part, continuous fibres (carbon, glass or Kevlar), which can be extruded with the help of a nozzle and thus fused with the part, giving it tenfold strength in addition to other properties, depending on the type of fibre chosen. The reinforcement strategy (number of lines, layers, orientation, etc.) can be chosen according to loading conditions.

The base material is either nylon or “Onyx”, a nylon filled with carbon micro-fibres. Onyx, when used alone, is five times stronger than ABS. With the addition of fibre reinforcement, it can offer the strength of aluminium.

Features

Printing volume: 32 x 13.2 x 15.4 cm

Layer thickness: from 0.1 to 0.2 mm

Very good dimensional stability

High strength

Rates

| Single rate | |

| Onyx or Nylon (base material) | €10 / 30 min |

| Fiberglass reinforcement | €2.40 / cm3 |

| Kevlar or HSHT* fibreglass reinforcement | €3.17 / cm3 |

| Carbon fibre reinforcement | €4.75 / cm3 |

*Optional – The volume of fibre reinforcement required is calculated when preparing the print files.

Only the first 15 / 30 minutes will be charged at the time of booking. The balance can be paid on site.

Crédit Photo : Markforged

3D Markforged Mark Two printer

Professional 3D printing of reinforced parts

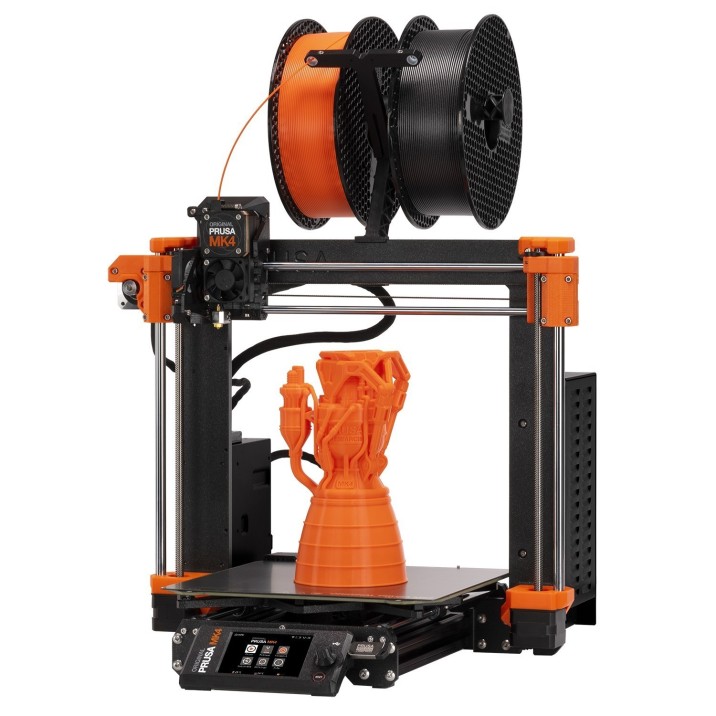

Crédit Photo : Makershop 3D

Crédit Photo : Makershop 3D

The 3D printing technology used at Fablab Descartes is FDM (Fused Deposition Modelling).

This technique consists in melting a filament of synthetic material, usually ABS (Acrylonitrile Butadiene Styrene) or PLA (Polyactic Acid) type plastic through a nozzle. A small wire of molten plastic with a diameter of about a tenth of a millimetre is deposited and forms the different layers of the 3D model.

In order to use these machines you must come with a 3D model created with CAD software (Solidworks, Blender, Freecad, Fusion360, Onshape, etc.) in .stl or .obj format.

You can also take part in one of our training courses or come and practice at Fablab to create your 3D model.

You will then have to pass your file through the slicer of the machine in question (Simplify3D, Cura or Slic3r) to generate the Gcode which will be interpreted by the machine.

Machines and features

All our 3D printers have a heated platen to improve the hold of the part on its support.

Ultimaker – Ultimaker 2 Extended Printing volume : 22,3 x 22,3 x 30,5 cm

Crédit Photo : Makershop 3D

3D printer Ultimaker 2 Extended

Print your modelled objects in 3 dimensions.

Crédit Photo : Makershop 3D

Crédit Photo : Makershop 3D

The 3D printing technology used at Fablab Descartes is FDM (Fused Deposition Modelling).

This technique consists in melting a filament of synthetic material, usually ABS (Acrylonitrile Butadiene Styrene) or PLA (Polyactic Acid) type plastic through a nozzle. A small wire of molten plastic with a diameter of about a tenth of a millimetre is deposited and forms the different layers of the 3D model.

In order to use these machines you must come with a 3D model created with CAD software (Solidworks, Blender, Freecad, Fusion360, Onshape, etc.) in .stl or .obj format.

You can also take part in one of our training courses or come and practice at Fablab to create your 3D model.

You will then have to pass your file through the slicer of the machine in question (Simplify3D, Cura or Slic3r) to generate the Gcode which will be interpreted by the machine.

Machines and features

All our 3D printers have a heated platen to improve the hold of the part on its support.

Anet A8 Printing volume: 20 x 20 x 20 cm

Only the first 15 / 30 minutes will be charged at the time of booking. The balance is to be paid on site.

Crédit Photo : Makershop 3D

3D printer Anet A8

Print your modelled objects in 3 dimensions.

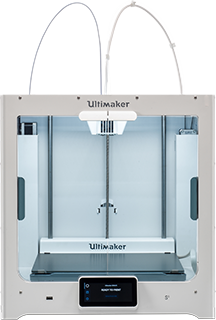

Crédit Photo : Makershop 3D

Crédit Photo : Makershop 3D

The 3D printing technology used at Fablab Descartes is FDM (Fused Deposition Modelling).

This technique consists in melting a filament of synthetic material, usually ABS (Acrylonitrile Butadiene Styrene) or PLA (Polyactic Acid) type plastic through a nozzle. A small wire of molten plastic with a diameter of about a tenth of a millimetre is deposited and forms the different layers of the 3D model.

In order to use these machines you must come with a 3D model created with CAD software (Solidworks, Blender, Freecad, Fusion360, Onshape, etc.) in .stl or .obj format.

You can also take part in one of our training courses or come and practice at Fablab to create your 3D model.

You will then have to pass your file through the slicer of the machine in question (Simplify3D, Cura or Slic3r) to generate the Gcode which will be interpreted by the machine.

Machines and features

All our 3D printers have a heated platen to improve the hold of the part on its support.

Ultimaker – Ultimaker S5 (FDM – Double extrusion)

Printing volume: 33 x 24 x 30 cm

Interchangeable pipes (0.4 and 0.8 mm available)

Only the first 15 / 30 minutes will be charged at the time of booking. The balance is to be paid on site.

Crédit Photo : Makershop 3D

3D printer ULTIMAKER S5

Print your modelled objects in 3 dimensions.

Crédit Photo : Shopbot

Crédit Photo : Shopbot

This Shopbot Buddy CNC machine allows you to machine wood (rough, plywood, medium) and some metals (aluminium) in 2D1/2 and 3D to make the objects of your choice (furniture, mouldings, etc.).

It is necessary to prepare the 2D/D files for subsequent processing in the machine software (VCarve Pro).

Features

- Machining volume: 610 x 1,219 x 127 mm

- Spit HSD 2.2 HP (1.6 kW)

Only the first 15 / 30 minutes will be charged at the time of booking. The balance is to be paid on site.

Crédit Photo : Shopbot

CNC milling machine

Machining wood and aluminium.

Crédit Photo : Brother

Crédit Photo : Brother

The digital embroidery Brother Innov-is NV2600 machine can be used both manually (like a conventional sewing machine) and by numerical control (to make designs, images or text, embroidered on your fabrics).

It is also possible to create your own designs to be set up on the proprietary software of the PE Design machine.

Features

- 7 drive claws

- 14 alphabets

- 227 integrated embroidery designs

Only the first 15 / 30 minutes will be charged at the time of booking. The balance is to be paid on site.

Crédit Photo : Brother

Digital embroidery machine

Create and realise embroidered designs on fabrics.

Crédit Photo : Roland

Crédit Photo : Roland

This Roland Camm 1 Pro GX-300 machine can cut materials such as vinyl, flex or flocking, to make stickers or T-shirt flocking for example.

To use it, you need to make a vectorised cutting contour (CAD or graphic editing software such as Illustrator, Photoshop, etc.) and transfer it to the machine via the CutStudio software.

Features

- Useful width: 73.7 cm

- Pressure: 50 gf at 85 cm/sec

Only the first 15 / 30 minutes will be charged at the time of booking. The balance is to be paid on site.

Crédit Photo : Roland

Vinyl cutting

Cutting materials for your signage.

Crédit Photo : Arduino

Crédit Photo : Arduino

Arduino is an open-source platform (the plans of the board are available free of charge) programmable electronics allowing to drive inputs (sensors) / outputs (mechanical actuators, display, leds, relays, etc.) to discover electronics and to learn programming.

Features

- Arduino UNO card

- Components (light sensors, resistors, leds, servomotor, etc.)

- 170-page booklet to learn about electronics and programming

Crédit Photo : Arduino

Arduino starter kits

Discover electronics and learn about programming.

Crédit Photo : Canon

Digital video camera

Capture and document your creations.

Crédit Photo : 3D Systems

Crédit Photo : 3D Systems

This 3D Systems portable scanner allows you to digitise 3D objects with millimetre precision, while reproducing colours with a resolution of 1,920 x 180 pixels.

It comes with software that allows you to scan, rework and export the scans in .stl, .obj, .ply or .wrl.

Features

- Perimeter of capture: max. = 1.60 m / min. = 20 cm

- View angles: horizontal = 45° / vertical = 57.5° / diagonal = 69°

- Nomber of frames per second: 30 fps

- Scan volume: min. = 0.2 x 0.2 x 0.2 m / max. = 2 x 2 x 2 m

- Operating temperature: 10 – 40°C

- Spatial resolution in x/y at 50 cm distance: 0.9 mm

- Depth resolution at 50 cm distance: 1 mm

Crédit Photo : 3D Systems

Scanner 3D Revopoint Pop3

Digitise large or medium volume 3D objects.

MORE

is available with our partners from Gustave Eiffel Univrsity and Paris-East Sup:

- Eav&t, large-format reprography equipment, large-format laser cutting, 3D printers, milling machine, wood workshop (band saw, band sander, lap sander, combined planer, planer, circular saw…),

- ESIPE, numerically controlled machines for metal machining, in particular milling machines and lathes,

- FCBA, 3D-LAB machines, its experimentation workshop dedicated to professionals aiming to:

- Experiment with additive manufacturing processes and their integration into a current industrial manufacturing process: molten wire deposition, glued powder, stereolithography

- Produce prototypes, models and functional parts for professional designers and manufacturers,

- Introduce professionals to the topographic optimisation of parts through 3D modelling and digital re-design.